Solar panel systems come in a large variety, sizes, and types. There are lots of specifications and parameters that need to be considered while choosing a solar panel system. Solar panels are an integral part of the solar panel system, and their selection matters a lot in the overall system performance.

Most customers look for the appearance, efficiency, and cost of the solar panels, but most are unaware that the type of solar panel affects all these factors. The type of solar panel used will affect the cost, performance, and installation of the system. You must know the kind of solar panel best for your application.

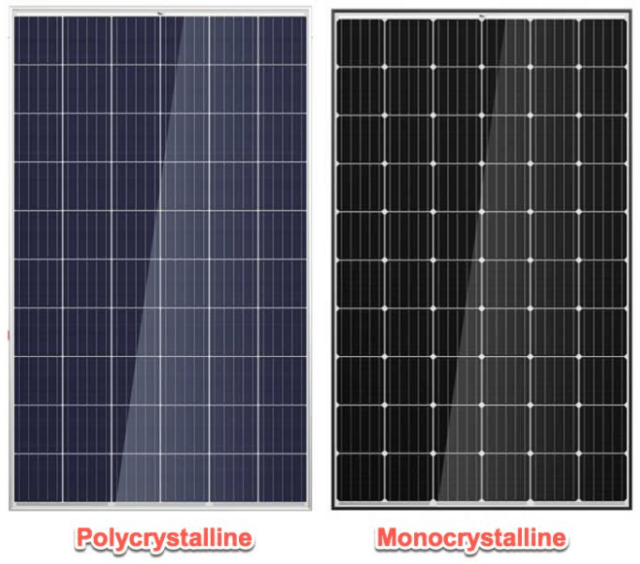

There are mainly three types of solar panels commercially available which are, thin-film, monocrystalline and polycrystalline. Each type has pros and cons and must be selected according to the need and requirements of the project. Among these types, polycrystalline and monocrystalline solar panels are the most commonly used panels.

Deciding the best type of solar panel for your application can be overwhelming. Here is a detailed comparison of the two most common types of solar panels. This comparison will help you in deciding the best solar panel type for your application.

Monocrystalline vs. Polycrystalline Solar panels:

These types of solar panels differ in every aspect from appearance, cost, effectiveness, method of construction, specifications, etc. These features make them suitable for different applications and conditions. Let’s have an overview of both these types, and then it would be easier to comprehend the differences between them.

Monocrystalline solar panels:

These are the oldest and most popularly used solar panels. These solar panels come with high efficiency and great aesthetics. Most people choose this type because of its uniform dark black appearance, which looks aesthetically pleasing. For rooftop installations, monocrystalline solar panels are a highly preferred choice.

As the name specifies, monocrystalline solar panels are composed of solar cells that are cut from one crystalline ingot (a large crystal), making them more pure and efficient than polycrystalline solar panels. They can easily be identified by their characteristic black appearance and are square with the corners chipped off.

Polycrystalline solar panels:

Polycrystalline or multi-crystalline solar panels are a popular choice for those looking to install a solar panel system on a restricted budget. But with lower cost as a benefit, there comes a disadvantage of reduced efficiency compared to monocrystalline solar panels.

Polycrystalline solar panels, as the name suggests, are made from several different silicon pieces. Small silicon pieces are melted together and then molded to make solar cells. Since they are made from different silicon pieces, they are less pure and less efficient—however, their manufacturing process help in reducing waste and use the raw material efficiently.

They can easily be identified with their distinctive sporadic blue colour, which is not pleasing and hence not a preferred option for customers.

Here is a comparison for both the types of solar panels, taking into account different comparative factors:

1. Construction:

Monocrystalline: Czochralski method is used for the manufacturing of monocrystalline solar cells. In this process, a “seed” crystal of silicon is placed in a vat of molten silicon at a very high temperature (the molten silicon must be pure). To get a single crystal of silicon, the seed is taken out of the vat. On cooling, the molten silicon creates a single large crystal of silicon. This large crystal is known as ingot, which is then thinly sliced into wafers; these wafers are then used to manufacture solar cells.

The most common monocrystalline solar panel used for residential purposes is composed of 60 solar cells.

Polycrystalline: they are also prepared using the same Czochralski method in which a “seed” crystal is placed in molten silicon. The difference is that the seed is not pulled out, like in monocrystalline manufacturing; instead, the whole vat of silicon is left to cool down. As it cools down, multiple crystals of silicon form. The various crystals in the wafer cause the erratic blue colour of the polycrystalline solar panels.

Like in monocrystalline solar panels, a general residential polycrystalline panel will have 60 to 72 solar cells.

2. Performance and efficiency:

Monocrystalline: solar panels made from these crystals have the greatest efficiency as compared to other types. Solar panels can never be 100% efficient; the most developed solar panels have an efficiency ranging between 17% to 22%. The higher efficiency is because they are made from a single silicon crystal; this creates less resistance for the electrons and allows them to flow easily through the cells.

Since monocrystalline solar panels are more efficient, they will require fewer solar cells to produce the same power output as a bigger-sized polycrystalline solar panel.

Polycrystalline: since it has multiple silicon crystals, it offers greater resistance to the electrons and, therefore, restricts the flow of current and hence, reduces efficiency. The efficiency of polycrystalline solar panels generally ranges between 15% and 17%.

For the same amount of power generated by monocrystalline solar panels, a greater number of polycrystalline solar panels will be needed. With the advancement in technology, the efficiency of polycrystalline panels is improving and approaching that of monocrystalline panels.

3. Cost:

Monocrystalline: manufacturing monocrystalline panels is a costly and challenging process; this causes the price of monocrystalline solar panels to be higher than other types. Greater power ratings and increased efficiency also make the manufacturers charge more for monocrystalline solar panels.

However, with advancements in technology, the price difference between the types is reducing.

Polycrystalline: polycrystalline solar panels are much cheaper than monocrystalline ones; this has made polycrystalline solar panels an excellent choice for residential applications that need to be done under a limited budget. These solar panels share a significant solar market because of the reduced cost.

Nevertheless, technology is improving, and this has caused the price difference between the monocrystalline panel and polycrystalline panel to reduce. This reduction has made people opt for monocrystalline panels as they are better in performance.

4. Lifespan:

Monocrystalline: they come with a longer lifespan as compared to polycrystalline panels because of the increased purity. Most manufacturers will give a 25 years warranty for a monocrystalline panel. If proper care is taken of the system, the panels are robust enough to last even more.

Polycrystalline: these panels also last for a very long time but less as compared to monocrystalline. Their warranty varies between different manufacturers and is often less than 25 years. However, these solar panels can also last several more years than their warranty period.

5. Appearance:

Monocrystalline: they are manufactured from a single silicon crystal, and therefore, there is greater uniformity in the cells. When sunlight reflects the surface, you can see a uniform dark black surface which often, customers find pleasing.

Polycrystalline: multiple silicon crystals in the panel cause the light to reflect non-uniformly, resulting in a non-uniform blue colour. People rarely like this blue colour. Most people avoid polycrystalline panels because of their appearance.

6. Temperature Co-efficient:

Monocrystalline: monocrystalline panels have higher temperature co-efficient, making them efficiently work even at high temperatures. This also indicates that the power output reduction with an increase in temperature is lesser than the polycrystalline panel.

Polycrystalline: these panels have a lower temperature co-efficient as compared to mono panels and, therefore, cannot work efficiently at high temperatures. The power output significantly reduces with increased temperature. If you install the panel in a hot region, then poly panels can be the wrong choice.

Conclusion:

Monocrystalline and polycrystalline panels are both commonly used types of solar panels. Their varying specifications and differences make them suitable for different applications. All in all, monocrystalline is always a preferred and better choice for most applications because of the more significant number of benefits it comes with. It is always better to carefully look at all the system specifications before purchasing any solar panel system.